Import Export Guandong Diesel common rail direct injection 0 445 120…

Table of Contents Components in Common Rail Direct Injection System - CRDI System: Working of CRDI System or Common Rail Direct Injection: Advantages of CRDI System: Disadvantages of CRDI System: Vehicles use CRDI system: Components in Common Rail Direct Injection System - CRDI System: Fuel tank Accumulator [Header] High-pressure relief valve

Everything To Know About Common Rail Direct Injection System

DI-D engines: operating characteristics. TDCi are turbocharged diesel engines with the Common Rail fuel injection system, installed on Ford cars. They were introduced in 2000. Some of these engines are manufactured in-house by the Ford Motor Company while others are produced by Groupe PSA (now Stellantis).

rail Direct Injection YouTube

Common Rail Direct Injection (CRDi): Most modern engine fuel systems use an advanced technology known as CRDi or Common Rail Direct Injection. Besides, both petrol and diesel engines use a common 'fuel rail,' which supplies the fuel to injectors. Furthermore, manufacturers refer to this technology as CRDi in diesel engines.

Why Choosing Common Rail for a Gasoline Direct Injection (GDI)? BlueStars Diesel

The Common Rail Direct Injection (CRDI) system stands as a cornerstone of modern diesel engine technology, revolutionising the efficiency, performance, and emissions characteristics of these powertrains.

work 2_1653663265.jpg)

How Does Common Rail Direct Injection (CRDI) Work?

fuel-injection system (injectors). The rail here acts as a pressure accumulator. Areas of application The common-rail fuel-injection system for engines with diesel direct injection (Direct Injection, DI) is used in the following vehicles: Passenger cars ranging from high-economy 3-cylinder engines with displacements of

How does Common Rail Direct Injection (CRDI) work? SkillLync YouTube

A common rail direct injection (CRDI) system is a highly developed fuel injection system that has revolutionized diesel engine efficiency, performance, and emissions. It combines several components to ensure the smooth and effective burning of fuel in an engine while reducing emissions. The main components of a CRDI system include the common.

Common Rail Direct Injection What is CRDi Technology? CarBikeTech

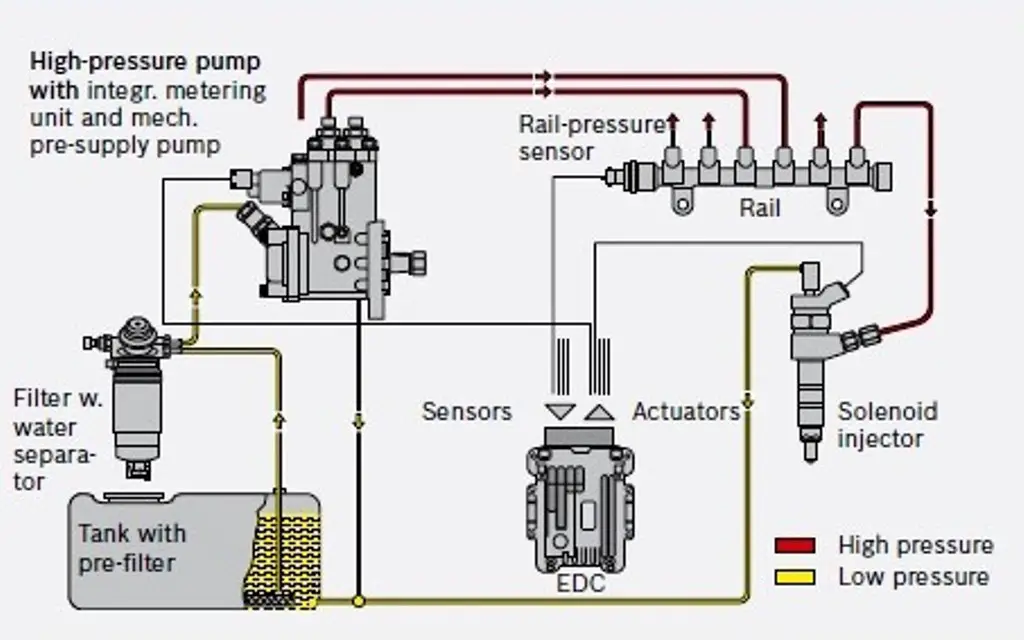

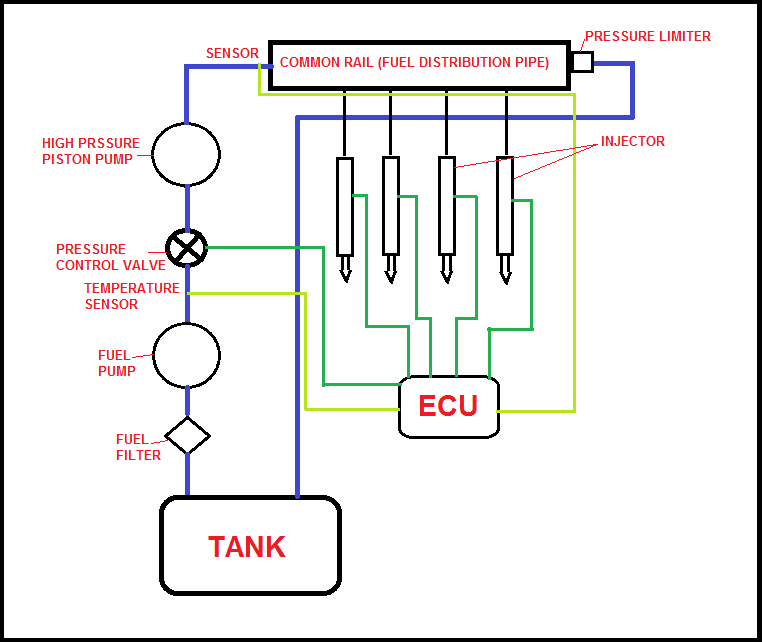

The common rail direct injection system is a modular design that has a common rail, electronic fuel pump, fuel tank, fuel filter, ECU, injectors and sensors. The fuel from the. fuel tank is fed into the filter and then to the fuel pump. A high-pressure pump pressurises the fuel. A pressure regulating valve is attached to the high-pressure pump.

DENSO Develops a New Diesel Common Rail System With the World’s Highest Injection Pressure

Common Rail Direct Injection System. In CRDI system the fuel is distributed to the injector from a high pressure accumulator and through a rail and this rail is common to all the cylinder. Because of this, it is called as common rail injection system. The quantity of the fuel and atomization are controlled electronically using a programmable.

L'injection directe common rail est un système d'injection directe de carburant pour moteurs

The main difference between common rail and direct injection diesel fuel systems lies in their method of fuel delivery. Conventional diesel fuel systems use a mechanical pump to deliver fuel to the engine, while common rail systems use a high-pressure pump to deliver fuel directly to the injectors.

Common rail direct fuel injection

Common rail direct fuel injection is a direct fuel injection system built around a high- pressure (over 2,000 bar or 200 MPa or 29,000 psi) fuel rail feeding solenoid valves, as opposed to a low-pressure fuel pump feeding unit injectors (or pump nozzles).

Common rail direct injection functions, parts, working student lesson

Diesel common rail direct injection (CRDI) and its benefits Common rail is a fuel injection system found in modern diesel engines. Common rail systems provide a level of flexibility which can be exploited for class leading emission control, power and fuel consumption.

Diesel common rail direct injection (CRDI) benefits DIESELO

Common rail injection allows the combustion process to be optimized so that less pollutant is produced from a smaller amount of fuel. Friedrichshafen, Germany With common rail fuel injection, the combustion process can be optimized to achieve low pollutant levels combined with lower fuel consumption.

Details about Diesel Marine Aeronautical engine Common Rail Direct Injection Details about

A CRDi engine, short for "Common Rail Direct Injection" engine, is an advanced type of fuel injection system specifically designed for diesel engines. It has revolutionised the way diesel engines function, offering numerous advantages over traditional fuel injection systems.

/NO1-CRD-589606003df78caebcdfb1f0.jpg)

What Is Diesel Common Rail Direct (CRD) Injection?

Common rail systems using direct acting piezoelectric injectors offer the ability to modulate the injection rate through their ability to control injector needle lift velocity and maximum lift. However, most common rail systems use indirect acting (servo actuated) fuel injectors where the pressure is relatively constant throughout the injection event and needle opening rate and maximum lift is.

Automobile Technology CRDI Rail Direct Injection)

Common rail direct injection system is mostly used in modern diesel engines. In this type of injection system, the fuel is supplied to the injectors with the required pressure and further supplied to the cylinders for the combustion process.

What is CRDI Common Rail Direct Injection In Diesel Engine, Working, Advantage and

Today's Common Rail injectors can perform multiple injections during a single combustion cycle and inject fuel into the engine at much higher pressures - up to 30,000 psi - through clearances as small as 1 micron.