รายการ 92+ ภาพ Process Flow Sheet ของ กระบวนการ ผลิต น้ำอัดลม ใหม่ที่สุด

Stamping Auto body panels •3 to 5 dies each • Prototype dies ~ $50,000 • Production dies ~ $0.75-1 • Forming dies • Trimming station

Fabrication TJSV Steel Fabrication and Galvanizing (India) Ltd

Introduction to Piping Fabrication (with PDF) Written by Anup Kumar Dey in Piping Design Basics Pipe fabrication can be defined as the process of cutting, bevelling, and welding piping components such as pipes, tees, elbows, flanges, reducers, etc., as dictated by the design documents.

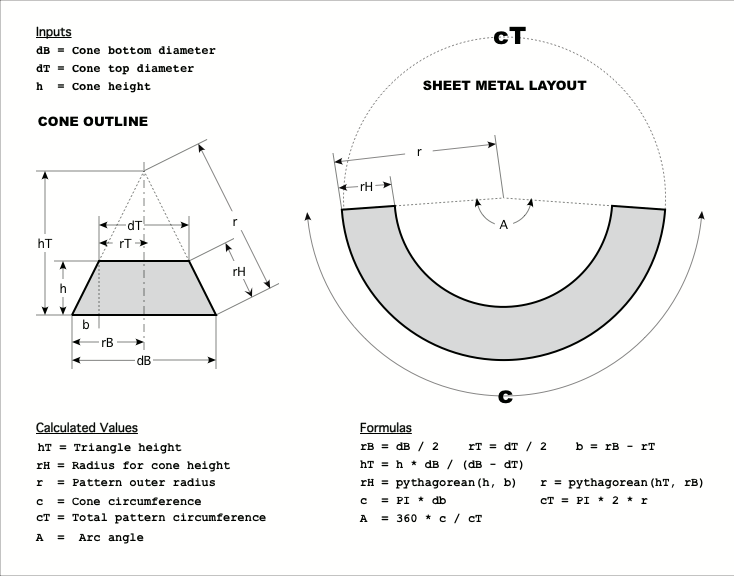

Formula Fabrication

Step 1: Draw Elevation View & Plan View for Full Cone Shape. Step 2: Divide Top View Circle of Cone in equal no. of Parts. Step 3: Measure Slant Height of the Cone in elevation view. Step 4: Draw Development Circle with Radius as Slant Height. Step 5: Measure Dividing Distance (L) From the Top view of Divided Circle.

Trigonometric Formula Sheet

The fabrication cost percentages for welded box beam and stiffened plate are 29-35 and 46-71% of the total costs, respectively, thus they can have a significant effect on optimum dimensions.

PIPE FABRICATION CALCULATIONS (PDF DOWNLOAD)

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed into the final part using press brakes and die tools. Parts can be finished with inserts, welding, surface

PIPE FABRICATION CALCULATIONS (PDF DOWNLOAD)

Download now of 2 Fabrication Formulas Fo rmulas: o Bend Allowance (BA) - The amount of added to the sum of the two leg lengths to obtain the flat pattern length. Bend Deduction (BD) - The amount removed from the sum of the two flange lengths to obtain a flat pattern. o o o Material Thickness (MT) - The gauge of the material in decimal form.

PIPE FABRICATION CALCULATIONS (PDF DOWNLOAD)

Pipe Fabrication Calculations & Basic's Rizwanulla Patan December 05, 2020. Unit :- 1 Module : Workshop Calculations. DOWNLOAD FREE STATIC PRESSURE CALCULATOR (Very useful for HVAC Engineer). 2023. ASME/ANSI B16.5 - Flanges and Bolt Dimensions Class 150 to 2500 (Download PDF Also) June 09, 2020. Follow On LinkedIn Rizwanulla.

Mathematics Formulas Riset

Fabrication Formulas _ SheetMetal.pdf The Basics of Applying Bend Functions 18-Limit, Fit, Tolerance 18-Limit, Fit, Tolerance Roller Cone Bit Geometry limits fits tolerances Cn- 4.4 Maintenance Practices-III Calculations Bending Distance K-Factor-I Solid Works Sheet Metal limitfittolerance-130704074006-phpapp01 unit-3-170228093759.pdf

Pipe Elbow Fabrication Formula Pdf Free quisevenkcoca Geometry formulas, Pipe, Formula

Easily Automate, Mange & Optimize Document Workflow. Register Now. Save Time Editing PDF Documents Online. No Installation Needed. Try Now!

Fabrication Formulas _ SheetMetal.pdf Sheet Metal Metalworking

Welding is an important process and has a very important part in industry, especially in the automotive, maritime, and energy sectors. Although welding has many advantages, it also has some disadvantages such as thermal expansion and shrinkage or microstructural transformations, which cause stresses.

Formula Student Car Fabrication Freelancer

Learn the basics of fabrication and engineering drawing with this comprehensive and practical guide. This PDF covers topics such as materials, tools, measurements, and welding techniques.

metal flowchart flowchart in word

PIPE FABRICATION CALCULATIONS (PDF DOWNLOAD) Rizwan khan December 29, 2020. Download This Lecture Notes in PDF File with Below Link. Download PDF. Tags: Piping PDF. Facebook. Twitter.

Conecalculator

Download Free PDF View PDF See Full PDF Download PDF BACK TO BASICS ESTIMATING SHEET METAL FABRICATION COSTS A Step-By-Step Guide to Understanding How Fabricated Parts Are Estimated Brought to you by . . . .

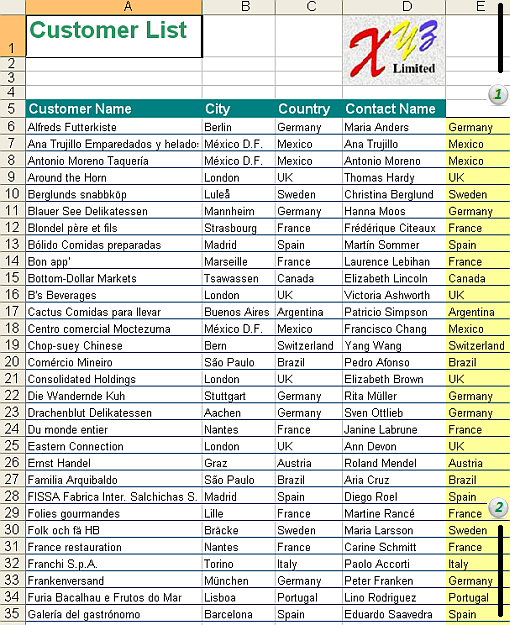

102 Useful Excel Formulas Cheat Sheet PDF (Free Download Sheet) Positive Numbers, Negative

Introduction. • Cutting and forming thin sheets. of metal usually. performed as cold working. • Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. • Plate stock > 6 mm thick. • Advantage - High strength, good dimensional. accuracy, good surface finish, economical mass. production (low cost).

Lista 91+ Foto Ejercicios Prácticos De Word Y Excel Para Oposiciones Pdf Gratis El último

You don't need to be an expert to edit PDFs. Download Soda PDF now! Specifically designed to help you collaborate with peers on your documents.

Fabrication process flow chart Download Scientific Diagram

Learn how to use the Drive 1 software to create and edit engineering drawings in this free PDF guide from the Department of Training and Workforce Development.